Products

Advanced Products

Fastener Engineering

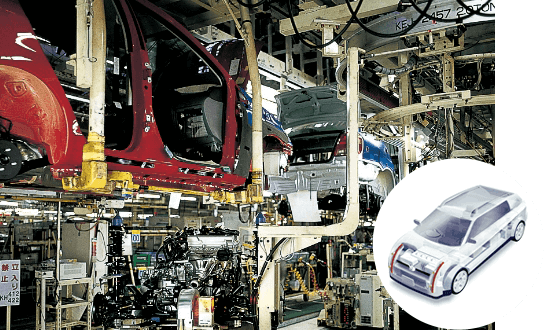

Offering the full range of fasteners required for automobile manufacturing "Fasteners are an indispensable part of automobile production lines. Additionally, the required functions of those fasteners vary greatly depending on the fastening application. Aoyama Seisakusho continues to develop fasteners that meet our customers' needs in every process, from stamping through final assembly.

One-of-a-kind products, based on our core technologies, that meet our customers' needs...

The required function and performance for fasteners vary greatly depending on the application in which they are used.

Aoyama-developed products, which are one step ahead of the competition, provide unseen strength to the vehicle, enabling it to run and function completely.

Responding to the fastener for engine which is the core part of vehicle with reliable technology

-

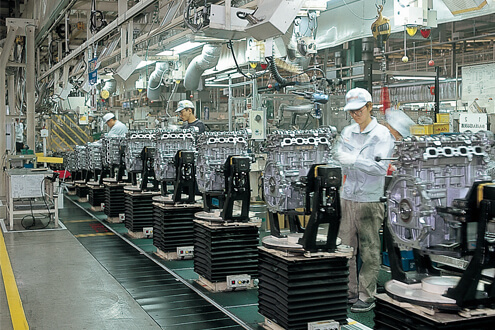

1Engine assembly process

Tightening reliability and high quality are required for the engine because of its use conditions.

Aoyama provides the fasteners that improve the workability such as NT studs, which were developed for the first time in the world, in addition to high-quality engine bolts.

Slit Locking Nut

The elasticity of slitting part delivers stable driving torque and highly-reliable flexure resistant performance.

NT Stud

Aoyama's original stud bolts in hexalobular shape, which is superior in implantability, realize the improvement of nuts' guiding property and cost reduction.

Engine Bolt

High strength critical engine fasteners, which are generated by the latest production technology and full-blown quality control system

Responding to the needs of vehicle production line with development and technological abilities

-

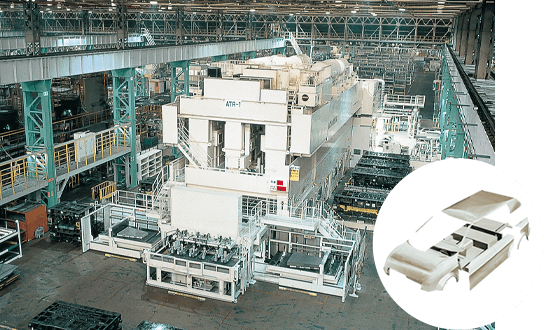

2Stamping process

Aoyama develop fasteners that are assembled during stamping process with the total fastening concept.

We propose fasteners that can be clinched inside dies during stamping process by using the pressure of the die.

Round High Piercing nut

Piercing nuts can be assembled during the stamping process with making a hole and clinching on the sheet metal.Able to eliminate welding process for the cost saving.

Piercing nut for Aluminum

These are the piercing nut responding to the changeover of vehicle steel plate to aluminum. The shape considering the surface pressure can prevent buckling.

-

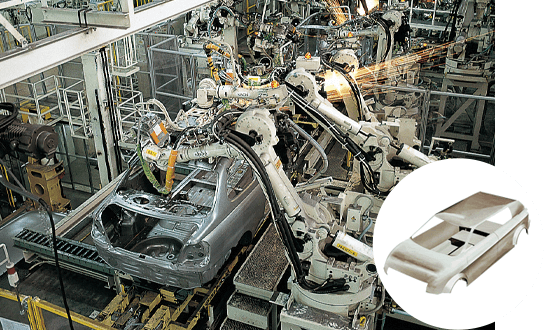

3Welding process

Aoyama's welding bolts and nuts assembled to the body contribute to the improvement of vehicles' reliability such as sealing performance and strengthening of welded seating face.

Hyper Sealing Nut

Welding nuts that adhere tightly to body at welding because of original shale of seating face to exercise high sealing performance

High-Strength Weld nut

High strength welding nuts using special materials, which contribute to space saving and weight saving

Fit-Weld Bolt

A ring adheres tightly and evenly to a body at welding to exercise high sealing performance

-

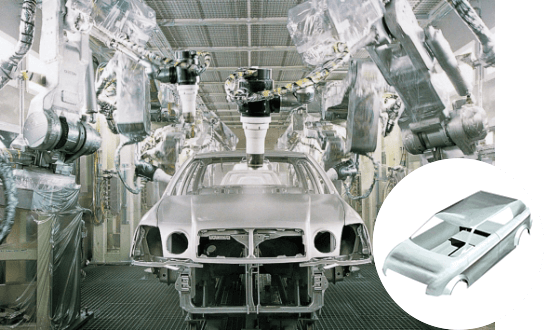

4Painting process

The paint film on a vehicle has a great impact on the fastening of the fastener.

Aoyama's high-functional fastener realizes a reduction in the total costs in fastening work including the removal and adherence prevention of paint film.

Open Weld

The Plastic lid prevents the infiltration of vinyl chloride sol. It removes masking work and reduces costs.

Tri-Cut Nut

Tri cutouts remove the paint film.

Fluted R Navitite®

Bolts with anti-cross threading and paint film removal function by cutouts

-

5Assembly process

The assembly process uses the fasteners most.

There is the culmination of fastener engineering here including modularization, auto-fastening, and workability improvements.

ND Bolt

The knurling tool integrates a nominal diameter bolt and a washer.

sealhead®

The Plastic at the screw head prevents the separation and flaws of paint. The torque lock at the threads prevents the loosening of the screw.

ET Screw®

Self-burring screw for thin plates. It achieves weight reduction by removing the weld nut

Navitite®

The screw thread at the tip guide prevents baking caused by diagonal insertion.

Ergoclip (Ergogrommet)

Aoyama's unique shape reduces insertion load. This prevents the assembly workers from getting sick.

Grounding bolt

The lock shape at the screw and the surface treatment with electric resistance considered assure stable body earth performance.