Quality and Production Control

Quality Control

The ideas that "Quality is made during the process" and "Defects should not be sent to the following process" are the basic principles of the process-based quality control system in Aoyama Seisakusho.

Fool-proof devices placed in every location and reliable eyes of the operator support the quality of Aoyama Seisakusho.

-

1Wire drawing

This process is to size wire rods purchased from a steel manufacturer suited for product manufacturing.

We strictly inspect the material of all wire rods.

Spark test

This test checks material components

Tensile test

This test checks material strength

-

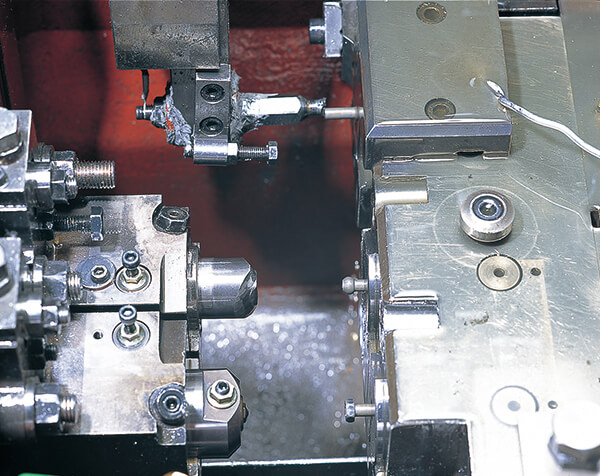

2Cold forming

This process is to form the head and body of a bolt from a wire rod.

We control the quality using fool-proof devices and every sort of quality check.

Die defect detector

The detector detects a poor shape accompanied by a die defect

Head percussion test

The test checks the strength of the body of the bolt.

-

3Thread Rolling

This process is to make threads on the body made during the heading process.

We install a washer for the bolt with the washer.

We maintain quality control similar to that of the heading process.

Washer defect detector

The detector prevents bolts without a washer from being sent to the following process.

Gauge check

We check the accuracy of screws

-

4Heat-treatment

This process is to make the bolt have specified strength by quenching and tempering it.

The strength is one of the important properties and we carry out the hardness test for all lots.

Hardness test

The test checks the hardness of the surface and the inside.

Management of

heat-treatment conditionsThe treatment time, furnace atmosphere, and temperature conditions are computer-controlled.

-

5Surface treatment

This process is to plate the bolt.

To satisfy the specified anti-rust performance, we define the best plating conditions for each product and control the conditions automatically.

Condition entry using A-PICS Kanban

The system automatically sets treatment conditions via the barcode.

Anticorrosion test

The test evaluates anti-corrosion performance with SST/CCT test

-

6Shipping

This process is to ship products to a customer.

To deliver correct products in necessary quantities by the delivery date, we check every box of products.

Automatic warehousing device

This is computer-controlled warehousing

Barcode check

To prevent wrong products, the system automatically collates the customer's Kanban with A-PICS's Kanban.

To customers

all over the world

Reliable products produced under the process-based quality control system in Aoyama Seisakusho

provide safety and reliability for drivers all over the world as a part of the vehicle.